What is a clean room?

Many factories and industrial parks are now often equipped with clean rooms to improve production quality. So what exactly is a clean room? Is this environment safe for workers? Is working in a clean room hazardous? What principles should workers follow when working in this special area?

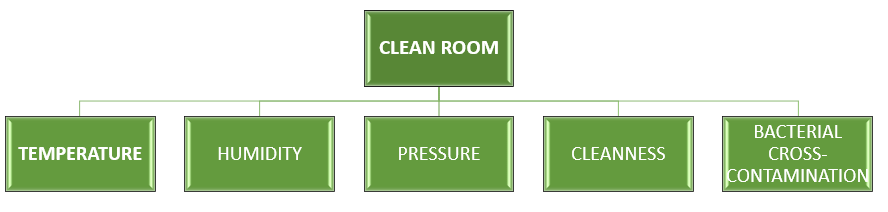

Cleanroom is a room built and used to minimize the entry and retention of airborne particles, while controlling other relevant room parameters such as temperature, humidity, pressure. when necessary. When all factors in the room are controlled, it will help minimize the contamination or cross-contamination of products during research and production, ensuring sterility.

CLEAN ROOM HISTORY AND DEVELOPMENT

Cleanrooms were first used in the medical field. The work of Pasteur, Koch, Lister and other pioneering biologists has shown that infection is the cause of many diseases, one of which is the loss of bacteria. sanitation in the environment. For the first time in the 1860s, Joseph Lister (a professor at the University of Glasgow) established a closed room system to limit dust and prevent infection at the Royal Infirmary of Glasgow. was an Infirmary founded by the University of Glasgow, today split into two parts called Glasgow Western Infirmary and Glasgow Royal Infirmary). This is the first primitive clean room.

The clean room system used for production was started to be used during the second world war to improve guns and military weapons. And now, clean rooms are used for many fields: medical, materials science and engineering, electronic components, physics, chemistry, biology, precision mechanics, pharmacy… Basically, all All contaminants need to be controlled to ensure product quality, worker safety and the integrity of research. A true cleanroom must meet the criteria for the number and size of particles in a given volume of air.

CLEAN ROOM APPLICATIONS ONLY

Cleanrooms play an important role of manufacturing plants in many areas:

– Pharmaceutical clean room:

The products created are guaranteed not to cause complications of bacterial infection for users.

Preventing the invasion of harmful bacteria in the production of medicinal drugs.

– Food clean room:

In the food production process, maximum prevention of the invasion and reproduction of harmful bacteria.

Food is better preserved and does not affect human health.

– Hospital clean room:

With operating room and blood bank, it helps to create a sterile environment, limiting the growth of pathogenic bacteria.

– Electronic clean room:

When manufacturing circuit boards, electronic chips, clean rooms help remove dust particles in the air, ensuring product accuracy.

– Cosmetics clean room

Cosmetic production is easy for bacteria to penetrate and destroy ingredients in cosmetics. The use of a clean room prevents bacteria from breeding during production and storage.

CLEAN ROOM STANDARDS ONLY

Cleanroom standards is one of the requirements to be met for any cleanroom. To be assessed as a clean room, it is necessary to ensure the following parameters:

Clean rooms, in addition to regulated temperature and pressure like conventional air-conditioned rooms, also need stricter requirements on pressure, cleanliness and cross-contamination. Because the air moves from a place of high pressure to a place of low pressure, controlling the pressure helps to prevent air, dust, organisms… from another area to the clean room area.

Room cleanliness is determined by the number of air and filter exchanges. The greater the number of wind exchanges, the lower the concentration of dust particles, reducing pollutants generated in the room. Therefore, with each different level of cleanliness, the number of air and filter exchanges is also different.

For clean rooms, cross-contamination is quite complicated and difficult to control because it can be caused by many causes both from inside and outside. Setting standards on cross-contamination helps to minimize the appearance of impurities and foreign ingredients that will destroy or reduce product quality.

Among them, the parameter of dust content is the most important. Based on the parameter of the number of dust particles in a certain size range, people are classified into different cleanroom levels .